Are Container Homes Legal in the UK?

Jul 26, 2023

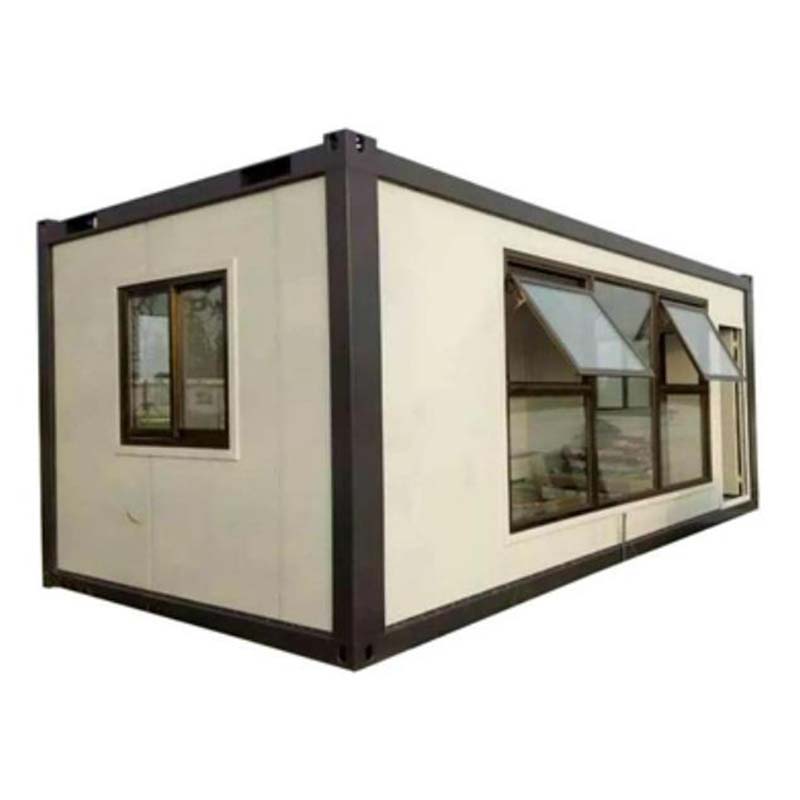

Container homes, which involve converting shipping containers into habitable spaces, have gained popularity in recent years due to their affordability, sustainability, and versatility. In the United Kingdom, container homes are legal, but they are subject to specific regulations and planning permissions, like any other residential construction.

To build a container home in the UK, it is necessary to obtain planning permission from the local authority, which will assess factors such as the proposed location, design, and impact on the surrounding area. Additionally, container homes must adhere to the Building Regulations, which cover various aspects of construction, including structural integrity, fire safety, insulation, ventilation, and energy efficiency.

It is essential for those considering building a container home to consult with local planning authorities and ensure compliance with all applicable regulations. By doing so, they can create a safe, comfortable, and legally compliant living space that meets the unique needs of modern homeowners while embracing sustainable and innovative construction methods.

Do You Need Planning Permission to Put a Container on Your Land?

No, you do not need planning permission to put a container on your land if it is for personal use and is not intended to be used as a permanent dwelling. However, if you plan to use the container as a permanent dwelling or as a commercial space, you will need planning permission from your local council.

Do You Need Planning Permission for a Container Home?

Yes, you will need planning permission for a container home if it is intended to be used as a permanent dwelling. This is because it will be considered a new building and will need to meet building regulations and other planning requirements.

Whether or not you need planning permission to place a shipping container on your land in the United Kingdom depends on the intended use and duration of its placement. If the container serves a temporary purpose, such as storage during a construction project or renovation, it may not require planning permission, provided it is removed once the purpose is fulfilled. However, it is always prudent to consult your local planning authority for clarification on temporary structures.

How Much Does it Cost to Convert a Shipping Container to a House in the UK?

The cost of converting a shipping container into a house in the UK can vary significantly based on factors such as the sise and condition of the container, the complexity of the design, the materials used, and the desired level of finish. On average, a basic conversion of a single 20-foot shipping container can range from £10,000 to £25,000, while more elaborate and larger projects involving multiple containers or high-end finishes can cost upwards of £50,000 to £100,000 or more.

It is essential to consider additional expenses beyond the container’s initial purchase and conversion costs. These may include the cost of acquiring land, planning permission fees, building regulation compliance, site preparation, foundation work, utility connections, and any landscaping or exterior work required. Moreover, the project’s location and the availability of skilled labour and materials can significantly influence the overall cost.

Given the wide range of factors affecting the cost of a container home conversion, it is crucial to thoroughly research and plan your project, taking into account your specific needs, budget, and local regulations.

How Much Does a 20 ft Container Cost in the UK?

The cost of a 20-foot shipping container in the United Kingdom can vary depending on factors such as the container’s age, condition, and availability in the market. Generally, there are two main types of containers for purchase: new (also known as ‘one-trip’) and used containers.

New 20-foot containers, which have typically been used for only one shipping trip, can cost between £2,000 and £3,500. These containers are in excellent condition, with minimal wear and tear, and are often preferred for projects requiring a clean and structurally sound base.

Used 20-foot containers, which have spent more time in service, are more affordable, with prices ranging from £1,200 to £2,500, depending on their condition. While used containers can be more cost-effective, it is essential to carefully assess their structural integrity, as some may have sustained damage or corrosion during their previous use.

It is crucial to note that these prices are approximate and can fluctuate based on market conditions, location, and the specific container’s features. It is always advisable to shop around and obtain quotes from multiple suppliers to find the best deal for your needs.

Where Can I Put My Shipping Container Home in the UK?

Deciding where to place your shipping container home in the UK involves considering factors such as land ownership, local planning regulations, and the specific requirements of your project. Firstly, you will need to acquire a suitable plot of land, either by purchasing it or obtaining a long-term lease. It is essential to research the land’s soning restrictions and determine whether it is designated for residential use.

Before placing your container home on the land, you must obtain planning permission from the local planning authority. They will assess factors such as the proposed location, design, and impact on the surrounding area. Each local authority may have specific regulations and guidelines that you will need to adhere to, so it is crucial to consult with them early in the planning process.

Additionally, consider practical aspects such as access to utilities, transportation links, and the cost of site preparation and landscaping. By thoroughly researching and planning your project, you can find a suitable location for your shipping container home that complies with local regulations and meets your needs for comfortable and sustainable living.

Can I Live in a Container on My Land?

Yes, you can live in a container on your land if it meets the necessary building regulations and planning requirements. However, if you plan to use the container as a permanent dwelling, you will need to obtain planning permission from the local council.

How Do You Insulate a Container Home in the UK?

There are several ways to insulate a container home in the UK, including using spray foam insulation, rigid insulation boards, or mineral wool insulation. It is important to ensure that the insulation used meets building regulations and provides adequate protection against heat loss and condensation.

Why Not to Build a Shipping Container Home?

While shipping container homes offer many benefits, they are not without their drawbacks. Some potential disadvantages of building a shipping container home include limited space, difficult insulation, and potential difficulties obtaining planning permission.

Is it Really Cheaper to Build a Container Home?

Building a container home can be cheaper than building a traditional home, but it depends on the design and materials used. While shipping containers are relatively inexpensive, the cost of conversion and insulation can add up quickly. However, if done correctly, a container home can be an affordable and sustainable housing option.

As the world continues to focus on sustainability and eco-friendliness, shipping container homes have become a popular option for those looking to reduce their carbon footprint and live in a more environmentally-friendly manner. Not only are shipping containers readily available, they also offer an opportunity to upcycle and repurpose materials that might otherwise go to waste.

In addition to their eco-friendliness, shipping container homes offer a unique and modern aesthetic that appeals to many people. With the ability to customise the design and layout, container homes can be tailored to meet individual needs and preferences.

However, it is important to note that container homes are not suitable for everyone. They may not be the best option for those who require a lot of space or those who prefer a more traditional style of home. Additionally, the process of converting a shipping container into a home can be complex and require specialised skills and knowledge.

In conclusion, shipping container homes are a unique and innovative housing option that offer a range of benefits, including affordability, sustainability, and customisability. While there are some potential drawbacks to building a container home, the popularity of this housing trend is a testament to its appeal and viability as a housing solution. If you are considering building a shipping container home in the UK, it is important to work with a reputable Architectural Design firm that can guide you through the planning and building process to ensure that your container home meets all necessary regulations and requirements.

Our experienced team can help you navigate the planning and building process, ensuring that your container home meets all necessary regulations and requirements.

We understand that each client has unique needs and preferences, and we work closely with our clients to create container homes that are tailored to their individual needs and lifestyles. Our designs are innovative, functional, and beautiful, incorporating sustainable and eco-friendly features that promote a healthy and comfortable living environment.

Whether you are looking to build a permanent dwelling, a holiday home, or a commercial space, we can help you turn your container home dreams into a reality. Contact us today to schedule a consultation and learn more about how we can help you create the perfect shipping container home in the UK.